2000L Fermenter Beer Fermentation Tank for Craft Beer Brewery

Tonsen Factory

Customer reference brewery

The fermenters and bright beer tanks fabricated by Tonsen following the more reasonable craft beer brewing request and clients special request, we make the layout well combined with the space. Our cellar tanks are fabricated by stainless steel 304 or 304L, which is the normal standard. All fittings using the top level Chinese supplier or the others fabricated in Germany, the stable standard on quality is priority. Besides we have more strict inspection on the whole tanks production. Each welding joint, polishing and pressure testing etc following the fixed procedure and guarantee we have 100% qualified product. Each tank with right serial number for accurate following up and service when clients are using these tanks.

All tanks are with good standard or are customized tanks are following special brewing recipe requirement, we have enough head space for fermentation. Tanks are installed with dimple plate cooling jacket, with right calculation on cooling speed, which achieve more accurate cooling temp control, all temp data within reasonable scope. The insider surface is qualified for beer production without dead contamination angle.

Our production on tanks is well following the regulation on pressure vessel regulation, meanwhile we fit the requirement of PED, ASME, AS1210 etc. We can product the tanks and system as the standard and certificate request from different countries and area.

All tanks are with good standard or are customized tanks are following special brewing recipe requirement, we have enough head space for fermentation. Tanks are installed with dimple plate cooling jacket, with right calculation on cooling speed, which achieve more accurate cooling temp control, all temp data within reasonable scope. The insider surface is qualified for beer production without dead contamination angle.

Our production on tanks is well following the regulation on pressure vessel regulation, meanwhile we fit the requirement of PED, ASME, AS1210 etc. We can product the tanks and system as the standard and certificate request from different countries and area.

Deatils of beer fermentation tank

| Application | Winery and brewery storage and fermentation |

| Material | SUS304, SUS316, red copper |

| Construction | 1. Dimple pad cooling jacket in the tank body and conical bottom, efficiently cooling the tank in all the parts 2. Cooling exchanging areas are available in different design 3. Conical bottom in 60 degree(70 or 90, due to different design) , it is design for the yeast fermentation processing 4. Temperature insulation: PU foam |

| Socket | Manhole, CIP hole, temperature probe, sampling valve etc |

Beer fermenter details as follow:

1)1 gallon to 20 gallon) and average 25% Head Space.

2) All tanks have a Dish top,

3)Cylinder body & 60/70° Cone Bottom.

4)Certified stainless steel(304,316) material for all tanks, with 100% TIG welded joints and seams with sanitary interior polish.

5) Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated.

6)All tanks use Tri-clamp connections, are designed for up to 14.7 PSI and tested at 30 PSI.

7) We can customize fabricate any tank to meet your brewery's space and height restrictions.

2) All tanks have a Dish top,

3)Cylinder body & 60/70° Cone Bottom.

4)Certified stainless steel(304,316) material for all tanks, with 100% TIG welded joints and seams with sanitary interior polish.

5) Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated.

6)All tanks use Tri-clamp connections, are designed for up to 14.7 PSI and tested at 30 PSI.

7) We can customize fabricate any tank to meet your brewery's space and height restrictions.

Brewhouse system/Beer Brewing equipment

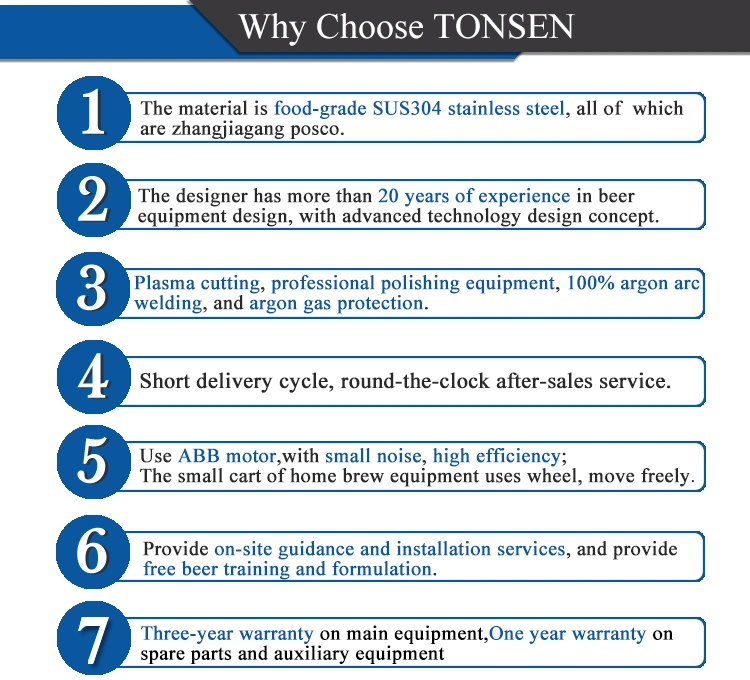

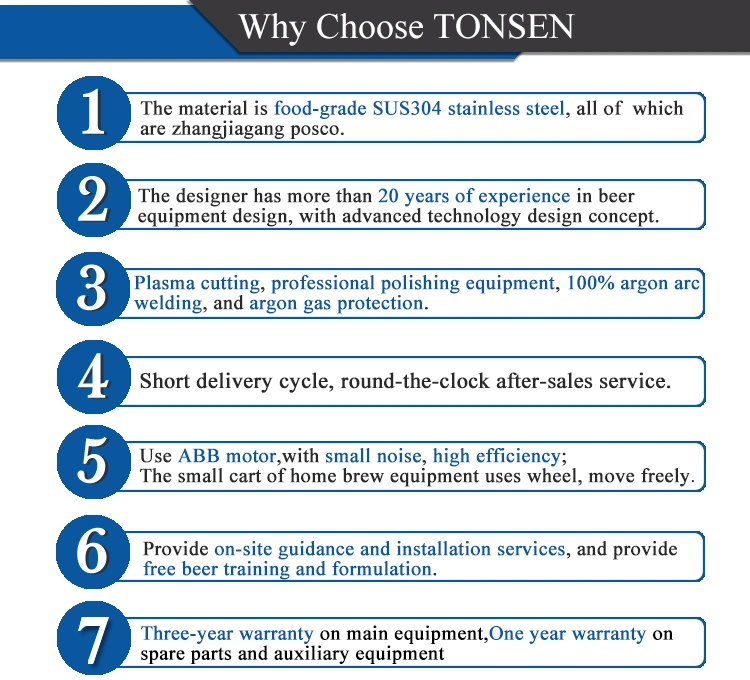

1. TurnKey brewery Project with high-level technology.

2. Custom made for any size.

3. International standard stainless steel 304,316 and red copper material.

4. Seamless Welding&8 times Inner polishing.

5. Advanced produce equipment.

6. Leading manufacturer of craft brewing equipment in China.

Brewery system equipment configuration list.

1. Milling System | Malt miller |

2. Brewhouse System | Mash/lauter tun, kettle/whirpool tun, hot water tank, plate heating exchanger etc |

3. Fermenting System | Fermenter, Bright beer tank |

4. Cooling System | Glycol water tank, chiller |

5. CIP System | Hot water tank, lye tank, CIP trolley |

6. Controlling System | PLC control or Instrument control |

Tonsen Factory

Shandong Tonsen Equipment Co., Ltd. is an international comprehensive enterprise specializing in R&D,production,technical support and services for beer equipment and wine equipment.We're located in Jinan City, Shandong province, China and our factory area covers 20000 square meter.

Customer reference brewery