Production introduction

Our Chillers has an outstanding history for providing cooling solutions to Beer brewing system. We provide specific solution to satisfy a variety of requirements. Customization is available.

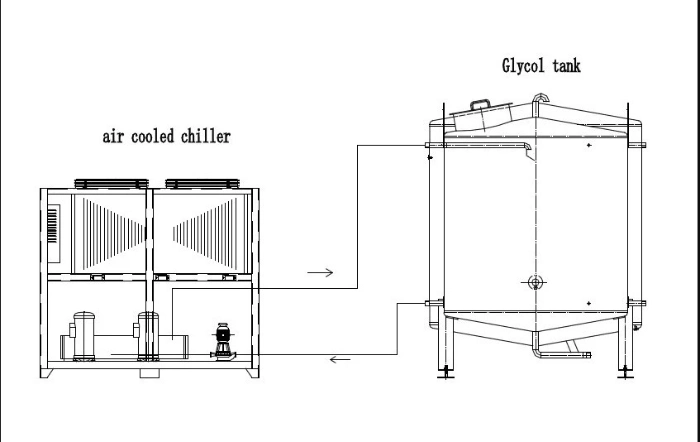

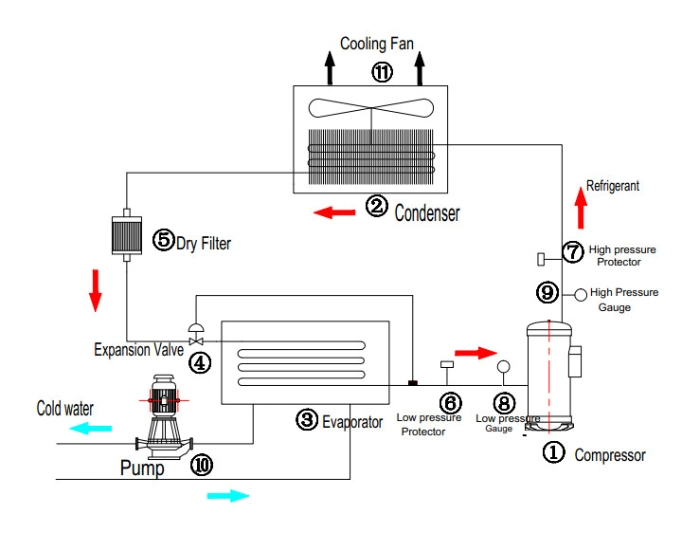

Beer cooling including glycol tank, chilling water tank, stainless steel plate heat exchanger, water chiller, refrigeration pipeline,etc. The core part of cooling is the chiller unit, the choice of brand and system adopted is particularly important. Commonly used refrigerants R22, R407C, R410A and R134a; The quality and stability of beer depend on the cooling capacity and the temperature control accuracy. 0.5C up and down is best.

You can give us the cooling capacity or provide the brewery capacity we help you choose a suitable model. If you have different requests, we also will provide the complete new solutions for your special demands.

Product show

Specification

| Air cooled scroll chiller | ||||||||||||||

| Model | MG-3C | MG-5C | MG-6C | MG-8C | MG-10C | MG-12C | MG-15CD | MG-20CD | MG-25CD | MG-30CT | MG-40CF | MG-50CF | ||

Cooling capacity | 0ºC | kw | 6.8 | 10.5 | 12.2 | 16.2 | 22.8 | 24.8 | 33.4 | 44.2 | 50.5 | 66.9 | 87.7 | 110.6 |

| -5ºC | kw | 5.7 | 8.9 | 10.3 | 13.8 | 19.3 | 21 | 28.4 | 37.6 | 43 | 56.8 | 74.5 | 94 | |

| Power | kw | 3.45 | 5.45 | 6.31 | 8.22 | 10.54 | 12.33 | 15.84 | 20.51 | 23.52 | 31.81 | 40.18 | 47.92 | |

| Power input | 3PH-380V-50HZ | |||||||||||||

| Refrigerant | Type | R22/R407C | ||||||||||||

| Control | Thermostatic expansion valve | |||||||||||||

Compressor | Type | Hermetic scroll type | ||||||||||||

| Power | kw | 2.84 | 4.36 | 5.2 | 3.5*2 | 4.4*2 | 5.2*2 | 6.6*2 | 8.7*2 | 10.2*2 | 8.7*3 | 8.7*4 | 10.2*4 | |

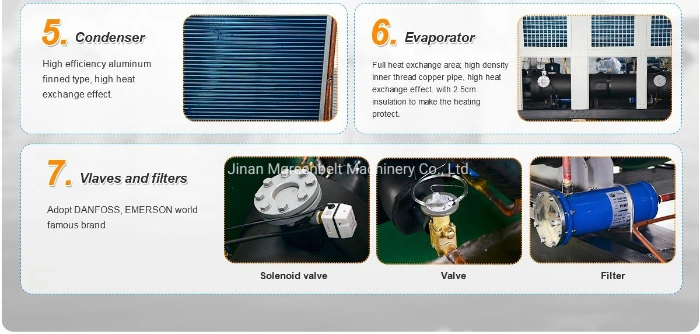

Evaporator | Type | SS Tank with coil or shell and tube | ||||||||||||

| m³/h Flow | 0ºC | 1.29 | 1.99 | 2.31 | 3.07 | 4.32 | 4.70 | 6.33 | 8.37 | 9.57 | 12.68 | 16.62 | 20.96 | |

| -5ºC | 1.17 | 1.83 | 2.12 | 2.84 | 3.97 | 4.32 | 5.84 | 7.73 | 8.85 | 11.68 | 15.33 | 19.34 | ||

Capacity | L | 50 | 70 | 70 | 120 | 200 | 200 | 270 | 350 | 350 | 450 | 580 | 580 | |

Inlet/Outlet | DN25 | DN32 | DN32 | DN40 | DN40 | DN40 | DN50 | DN50 | DN50 | DN65 | DN65 | DN65 | ||

Condenser | Type | High efficiency hydrophilic aluminum foil finned type | ||||||||||||

| kw Power | 0.19 | 0.52 | 0.52 | 0.24*2 | 0.46*2 | 0.46*2 | 0.55*2 | 0.78*2 | 0.78*2 | 1.32*2 | 0.78*4 | 0.78*4 | ||

pump | Type | High efficiency, low noise centrifugal water pump or SS water pump | ||||||||||||

| Power | kw | 0.37 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | |

| lift | m | 24 | 25 | 24 | 20 | 20 | 20 | 20 | 20 | 20 | 21 | 20 | 19 | |

Protection System | Compressor overheat protection, high/low pressure protection,phase sequence/missing protection, flow rate protection, anti-frozen protection. | |||||||||||||

Dimension | L | mm | 1120 | 1220 | 1220 | 1430 | 1610 | 1610 | 1870 | 2120 | 2120 | 2700 | 2300 | 2300 |

| W | mm | 600 | 690 | 690 | 780 | 820 | 820 | 900 | 1000 | 1000 | 1120 | 1860 | 1860 | |

| H | mm | 1200 | 1200 | 1200 | 1450 | 1500 | 1500 | 1600 | 1720 | 1720 | 1800 | 1800 | 1800 | |

| Wight | kg | 150 | 200 | 230 | 310 | 450 | 500 | 750 | 850 | 900 | 1150 | 1350 | 1600 | |

Product's details

User's site

Certificates for reference

Company introduction

Mgreebelt was founded in 2003. Our factory is located in Shandong Province, covering a total area of 34,000 square meters. We have served with comprehensive and professional refrigeration system solutions for more than 3500 companies from all over the world.

We mainly supply industrial Chillers, Cooling Towers, Heat Exchangers and Components. We insist on providing high quality products using key components of world famous brands such as Copeland/Panasonic compressors,Danfoss filters, Emerson valves, Schneider electric parts, etc.

Our range is highly recognized by customers. Our goal is to be your one-stop supplier of refrigeration system requirements.

Packing and shipment

FAQ

Q1: How to choose the right chiller?

A1:

1)water chiller type: Air cooled or water cooled

2)Cooling capacity: _____ Kcal/hr or _____KW or _____Tons

3)Refrigerant: R22 or R407c or R410a or others

4) Power supply voltage : ______ PH/V/HZ

5) Inlet and outlet temperature

6). Do you have the requests for the water flow rate , water pressure and water quality?

7). For what kind of equipment or cooling system( Close loop or open loop ) in your side?

8). What is the maximum ambient working temperature in your factory

Q2: What power supply chiller you can produce?

A2: Our standard power supply is 3phase-380V-50Hz, Customzied different for optaions, like 3phase- 415V,440V,460V,480V,- 50Hz or 60Hz

Q3: Can you supply C/O, FORM E?

A3:Yes, we can.

Q4:What refrigerant you can supply?

A4: We have R22, Eeo friendly R407c, R410a, R134a, depends on your choice.

Welcome your inquiry today!