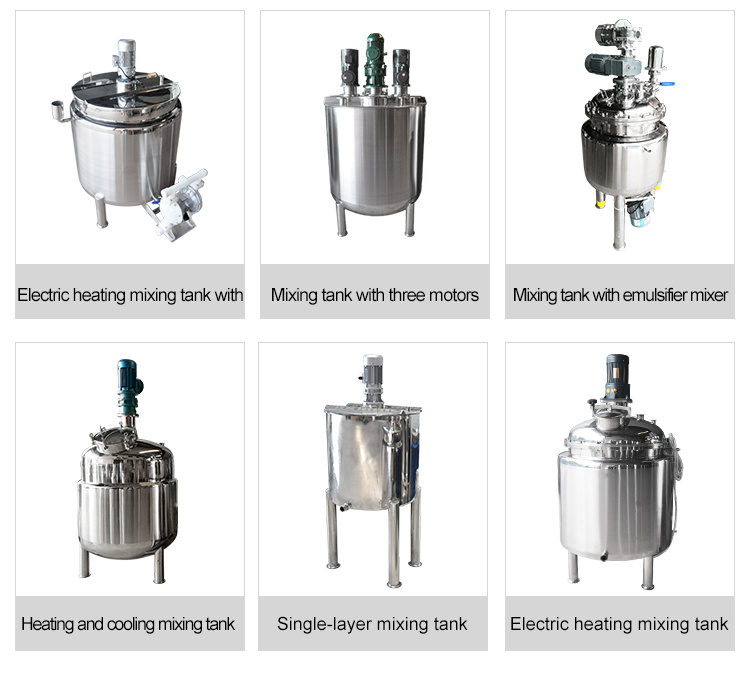

Tag:Mixing tank with emuslfiying high shear pump for cosmetics,shampoo,lotions,toothpaste,creams

Working Principle

By the strong force of high speed of homogenizer (emulsifier), the materials will go through the narrow space of the emulsifying head, it forms a powerful circulation in the vessel. In the middle part, the center blades and outer low speed anchor rotates in opposite direction. It performs great shearing, impact, and dispersion in the vessel. It will help to blend, mixer, emulsify, and homogenize the product in the vessel, and increase the stability, smoothness and luster of cream products. The emulsifying (mixing) head is exchangeable for your various products.

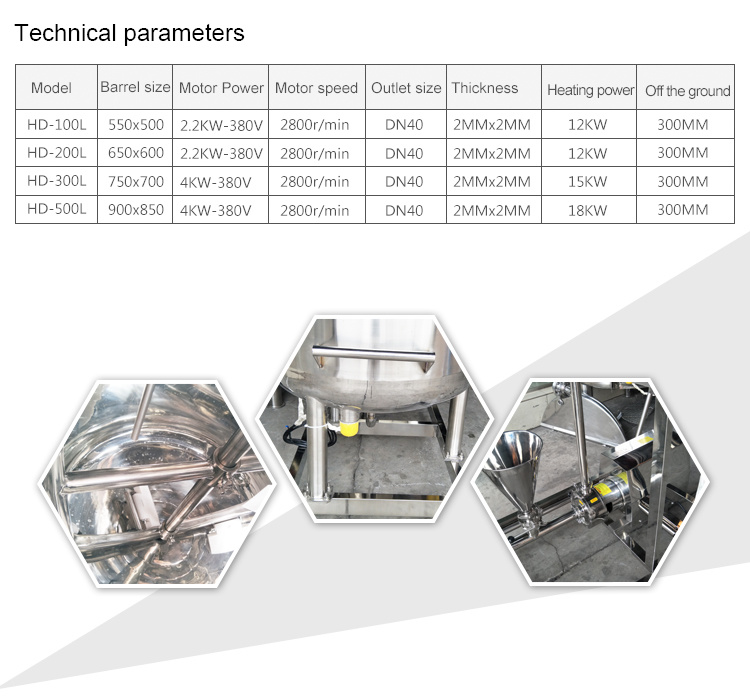

Technical Parameters

Features

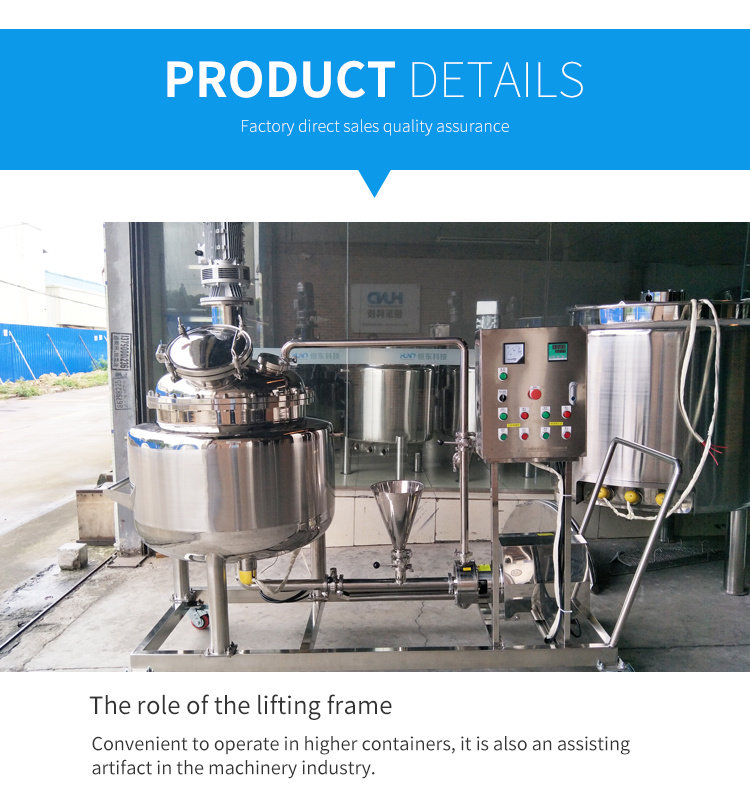

1.Machine consists of vacuum-resistant vessel with jacket for heating and cooling. Equipped with high speed homogenizer, scraping agitator, vacuum pump, and hydraulic pump for lifting, heating & cooling system.

2.Scraping unit is with moveable teflon scrapers to scrape off the materials on the tank wall and the anchor to move the materials to the center area to get better blending and mixing. The teflon scrapers are maintained manually and easily without any tool.

3.Our vacuum emulsifying equipment equipped with heating & cooling system which simplifies the processing. Within this same equipment, you can do from heating-melting-emulsifying-air bubble reduction(by vacuum)-cooling without changing vessels, it saves lot of labor and time for your production.

4.All contacted parts of equipments are SUS316L,the product homogenized in vacuum and close vessel can be sanitary and high quality.

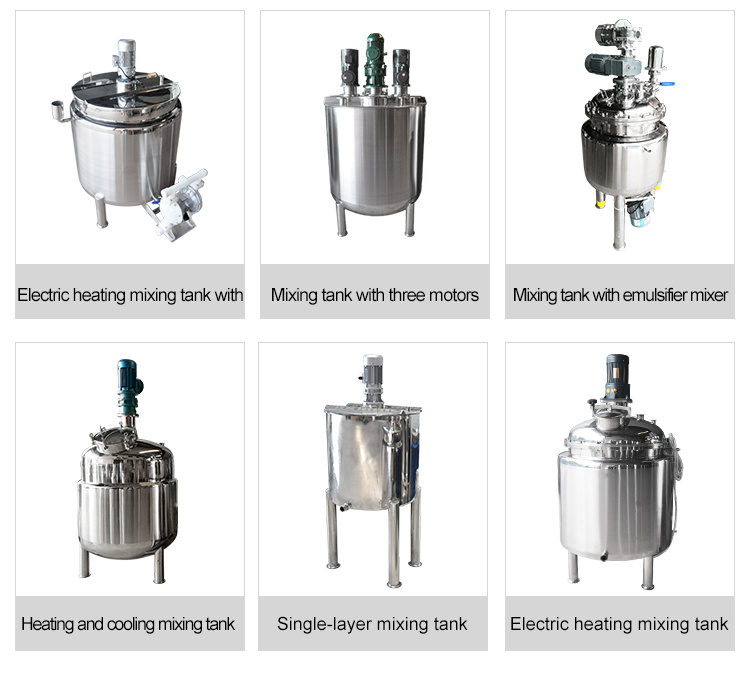

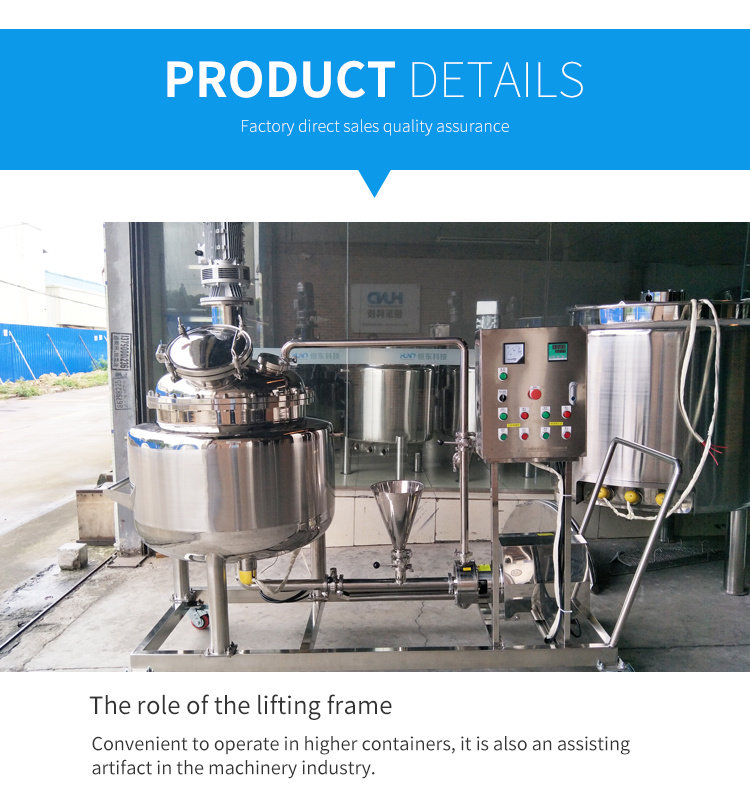

Product Show

About HUNDOM

Guangzhou Hundom Machinery Equipment Co., Ltd.has been manufacturing colloid mill, jacketed kettle, rotor pump, mixing tank and other machinery equipment for 14 years , putting quality as our first consideration. We own a team with rich experience in the field, if you have any question, contact us for the professional answer.

Guangzhou Hundom Machinery Technology Co.,Ltd.

Add:No. 115, No. 7, Haina Industrial Park, Shibi Street, Panyu District, Guangzhou City, Guangdong Province, China

Salesperson:Sherly Tang

Tel:+86-020-89081205

Mobile:+86-138-2213-2643

Welcome to visit our factory !

Working Principle

By the strong force of high speed of homogenizer (emulsifier), the materials will go through the narrow space of the emulsifying head, it forms a powerful circulation in the vessel. In the middle part, the center blades and outer low speed anchor rotates in opposite direction. It performs great shearing, impact, and dispersion in the vessel. It will help to blend, mixer, emulsify, and homogenize the product in the vessel, and increase the stability, smoothness and luster of cream products. The emulsifying (mixing) head is exchangeable for your various products.

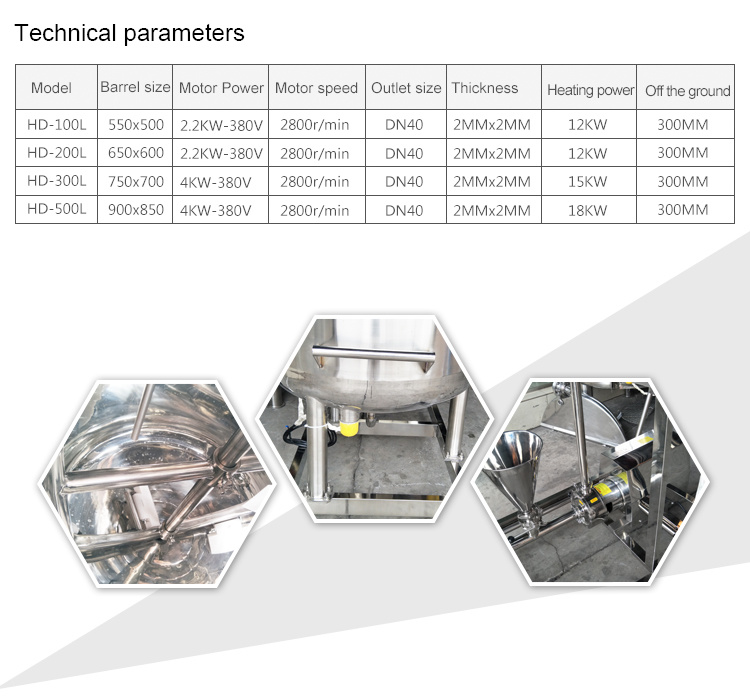

Technical Parameters

| Model | Barrel size | Power(kw) | Speed(r/min) | Outlet | Thickness(mm) | Heating (kw) |

| HD-100L | 550X500 | 2.2 | 2800 | DN40 | 2 | 12 |

| HD-200L | 650X600 | 2.2 | 2800 | DN40 | 2 | 12 |

| HD-300L | 750X700 | 4 | 2800 | DN40 | 2 | 15 |

| HD-500L | 900X850 | 4 | 2800 | DN40 | 2 | 18 |

| Customized | Customized | Customized | Customized | Customized | Customized | Customized |

1.Machine consists of vacuum-resistant vessel with jacket for heating and cooling. Equipped with high speed homogenizer, scraping agitator, vacuum pump, and hydraulic pump for lifting, heating & cooling system.

2.Scraping unit is with moveable teflon scrapers to scrape off the materials on the tank wall and the anchor to move the materials to the center area to get better blending and mixing. The teflon scrapers are maintained manually and easily without any tool.

3.Our vacuum emulsifying equipment equipped with heating & cooling system which simplifies the processing. Within this same equipment, you can do from heating-melting-emulsifying-air bubble reduction(by vacuum)-cooling without changing vessels, it saves lot of labor and time for your production.

4.All contacted parts of equipments are SUS316L,the product homogenized in vacuum and close vessel can be sanitary and high quality.

Product Show

About HUNDOM

Guangzhou Hundom Machinery Equipment Co., Ltd.has been manufacturing colloid mill, jacketed kettle, rotor pump, mixing tank and other machinery equipment for 14 years , putting quality as our first consideration. We own a team with rich experience in the field, if you have any question, contact us for the professional answer.

Guangzhou Hundom Machinery Technology Co.,Ltd.

Add:No. 115, No. 7, Haina Industrial Park, Shibi Street, Panyu District, Guangzhou City, Guangdong Province, China

Salesperson:Sherly Tang

Tel:+86-020-89081205

Mobile:+86-138-2213-2643

Welcome to visit our factory !