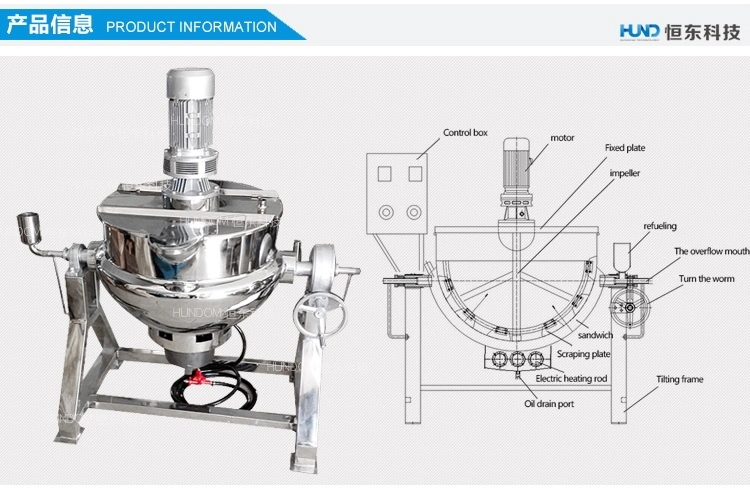

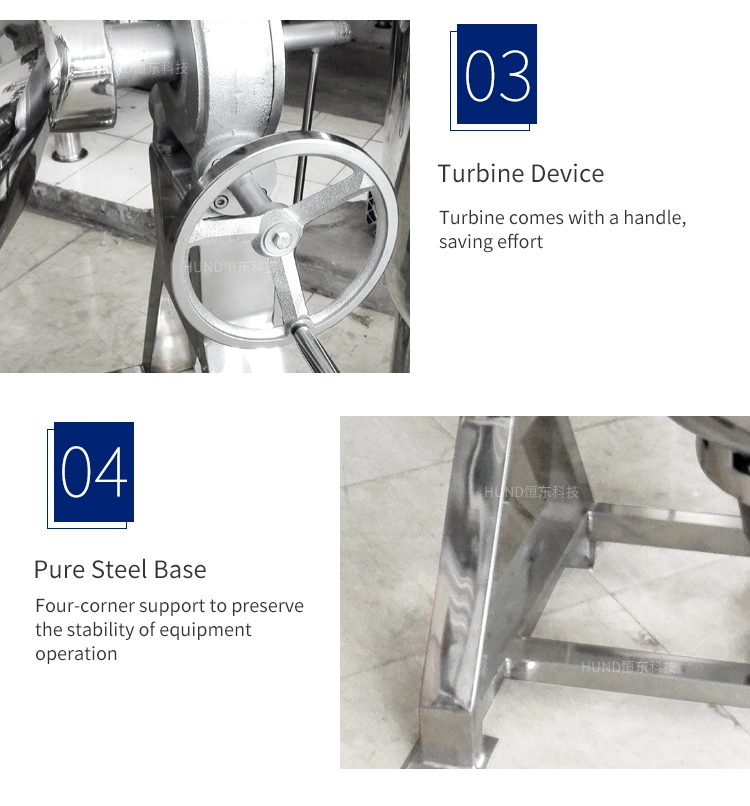

Structure

Cooking jacket kettle is composed of kettle,bracket,worm wheel and worm etc. The kettle can revolve within 180°, the equipment is used for open concentration,mainly for decocting and concentration of liquid in industries of pharmaceutical industry,food industry,chemical industry and light industry etc.Contact area of the equipment with aterials is made of stainless steel SUS304,which has perfect corrosion-proof performance,and is highly endurable according to GMP requirements.Blender also can be added according to customer requirements.

Specifications

1. Use electricity as heating source

2. Large heating surface

3. High heat efficiency

4. Beautiful surface

Application

The stainless steel jacket kettle can be applied to a wide variety of foods processing, such

as candy, medicine, dairy, liquor, cake, candied fruit, drink, canned goods, sauced meat etc.

It also can be used in making soup, cooking stir-fry, stewing meat, cooking porridge and so

on, and it is a wonderful equipment to improve quality, reduce time and improve working

conditions during foods processing.

Features

The voltage is 380V, and it is equipped with electrical bar. Heat transfer oil in the interlayer.

Big heating surface, high heat efficiency, short boiling time, temperature easy to be controlled.

Steam Jacket kettle

with Dimple jacket inside the walls for steam inject and heating. It takes the steam as thermal source. The inner surface contacted with the product are all SUS304 Or SUS316.

Electrical Jacket Kettle

Compared with steam heating, the heating temperature of the electrical jacket kettle is higher than steam jacket kettle, Which can shorten the cooking time.

Technical Parameter

| Model | HD50 | HD100 | HD150 | HD200 | HD300 | HD400 | HD500 |

| Volume(L) | 50 | 100 | 150 | 200 | 300 | 400 | 500 |

| Working pressure in jacket(Mpa) | <0.2 | ||||||

| Evaporating quantity(kg/h) | 30 | 40 | 50 | 65 | 75 | 100 | 150 |

| Heating area(m²) | 0.4 | 0.45 | 0.76 | 1.0 | 1.15 | 1.44 | 1.90 |

| Energy consumption(kg/h) | 33 | 44 | 55 | 72 | 90 | 110 | 165 |

| Weight of equipment(kg) | 170 | 190 | 210 | 230 | 320 | 360 | 485 |

| Width(mm) | 720 | 800 | 1350 | 1400 | 1450 | 1500 | 1600 |

| Height(mm) | 600 | 650 | 660 | 700 | 800 | 850 | 900 |

| Lenght(mm) | 830 | 950 | 1000 | 1100 | 1110 | 1140 | 1150 |

Product Show

About HUNDOM

Guangzhou HUNDOM Machinery Equipment Co., Ltd. was founded in 2003, is a high-tech enterprise integrating R&D, production and sales. It has more than 17 years of mechanical manufacturing experience. Main production: homogeneous emulsion tank, high-speed mixing tank, heating mixing tank, emulsification pump, colloid mill, conveying pump, filters etc. HUNDOM has mature technology and high quality products to meet various requirements in the field of food, pharmaceutical and chemical industry.

With a high level of R&D system, HUNDOM constantly strives to improve product quality and technical standards, constantly develops product functions to enhance product life and adherence to precision manufacturing. The ex-factory products need to undergo strict quality inspection procedures to ensure that they meet the quality requirements and inspection standards of all walks of life. The mature technology and rigorous attitude are the guarantee of HUNDOM Technology's product quality, to think what the customer thinks, and pleased what the customer likes. Provide a reasonable and effective equipment solution. Please believe us: there are high quality products, mature facilities and engineering teams waiting for you. Let's discuss, make decisions and make progress together with you.