Features

1.Compact structure, simple operation, easy maintenance,

2.Stable running, high efficiency, long service time

3.Good self-priming capacity

Working condition

Flow:6.3~400m3/h

Head:5~132m

Speed:2900,1450r/min

Power:0.55~110KW

Inlet diameter:50~200mm

Maximum working pressure:1.6Mpa

Maximum ambient temperature: 50ºC

Maximum medium temperature: 80ºC(up to 200 in case of special requirement)

Medium PH value: 6-9(cast iron), 2-13(stainless steel)

Maximum medium gravity: 1240kg/m

Application

1. For urban environmental protection, construction, fire, chemical, pharmaceutical, dyestuff, printing, brewing, electricity, electroplating, paper, petroleum, mining, equipment cooling, tanker unloading.

2. For fresh water, sea water and chemical liquid with acid and alkali, slurry with general paste (medium viscosity ≤ 100 centipoise, up to 30% solid-containing content).

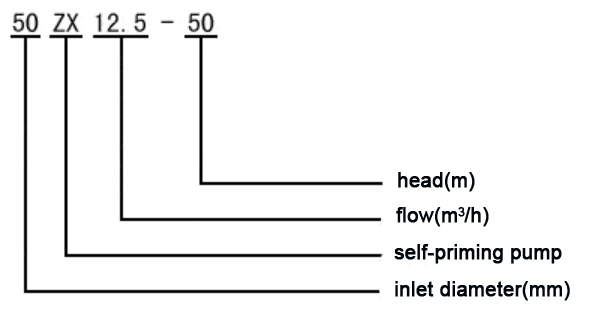

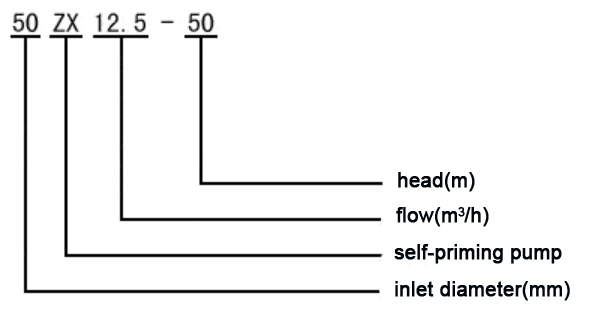

Model instruction

50ZX12.5-50

Technical parameter

For more detailed specification and performance data , please contact us directly by email or call.

After Service:

To satisfy customers, the company provides the users with before-sale, in-sale and post-sale full respect services.

Item of service

·Technical training Equipment evaluation

·Installation and debugging Troubleshoot

·Maintenance Update and improvement

Commitment to the service

√ One-year warranty. Provide technical support free all-life of the products.

√ Keep all-life contacting with clients, get feedback on use of the equipment and make the products quality continually perfected.

√ Hot-line of service is available in 24h, responded in 8h.

1.Compact structure, simple operation, easy maintenance,

2.Stable running, high efficiency, long service time

3.Good self-priming capacity

Working condition

Flow:6.3~400m3/h

Head:5~132m

Speed:2900,1450r/min

Power:0.55~110KW

Inlet diameter:50~200mm

Maximum working pressure:1.6Mpa

Maximum ambient temperature: 50ºC

Maximum medium temperature: 80ºC(up to 200 in case of special requirement)

Medium PH value: 6-9(cast iron), 2-13(stainless steel)

Maximum medium gravity: 1240kg/m

Application

1. For urban environmental protection, construction, fire, chemical, pharmaceutical, dyestuff, printing, brewing, electricity, electroplating, paper, petroleum, mining, equipment cooling, tanker unloading.

2. For fresh water, sea water and chemical liquid with acid and alkali, slurry with general paste (medium viscosity ≤ 100 centipoise, up to 30% solid-containing content).

Model instruction

50ZX12.5-50

Technical parameter

| Model | Flow(m3/h) | Head(m) | Power(kw) | Speed(r/min) | Self-priming height |

| 25ZX3.2-20 | 3.2 | 20 | 1.1 | 2900 | 6.5 |

| 32ZX3.2-20 | 3.2 | 20 | 1.1 | 2900 | 6.5 |

| 32ZX3.2-50 | 3.2 | 50 | 3 | 2900 | 6.5 |

| 40ZX6.3-20 | 6.3 | 20 | 1.5 | 2900 | 6.5 |

| 40ZX10-40 | 10 | 40 | 4 | 2900 | 6.5 |

| 50ZX15-12 | 15 | 12 | 1.5 | 2900 | 6.5 |

| 50ZX18-20 | 18 | 20 | 2.2 | 2900 | 6.5 |

| 50ZX12.5-32 | 12.5 | 32 | 3 | 2900 | 6.5 |

| 50ZX20-30 | 20 | 30 | 4 | 2900 | 6.5 |

| 50ZX14-35 | 14 | 35 | 4 | 2900 | 6.5 |

| 50ZX10-40 | 10 | 40 | 4 | 2900 | 6.5 |

| 65ZX30-15 | 30 | 15 | 3 | 2900 | 6.5 |

| 65ZX25-32 | 25 | 32 | 5.5 | 2900 | 6 |

| 80ZX35-13 | 35 | 13 | 3 | 2900 | 6 |

| 80ZX43-17 | 43 | 17 | 4 | 2900 | 6 |

| 80ZX40-22 | 40 | 22 | 5.5 | 2900 | 6 |

| 80ZX50-20 | 50 | 20 | 5.5 | 2900 | 6 |

| 100ZX80-20 | 80 | 20 | 11 | 2900 | 6 |

| 100ZX100-20 | 100 | 20 | 11 | 2900 | 6 |

| 100ZX70-75 | 70 | 75 | 30 | 2900 | 6 |

| 150ZX180-28 | 180 | 28 | 30 | 2900 | 6 |

| 150ZX170-65 | 170 | 65 | 55 | 2900 | 5 |

| 150ZX160-80 | 160 | 80 | 55 | 2900 | 5 |

| 200ZX400-32 | 400 | 32 | 55 | 1450 | 5 |

| 200ZX280-63 | 280 | 63 | 90 | 1450 | 5 |

| 200ZX350-65 | 350 | 65 | 110 | 1450 | 5 |

| 250ZX550-32 | 550 | 32 | 75 | 1450 | 5 |

| 250ZX400-50 | 400 | 50 | 90 | 1450 | 5 |

| 250ZX450-55 | 450 | 55 | 110 | 1450 | 5 |

| 300ZX600-32 | 600 | 32 | 90 | 1450 | 5 |

| 300ZX500-50 | 500 | 50 | 110 | 1450 | 5 |

| 300ZX550-55 | 550 | 55 | 132 | 1450 | 5 |

After Service:

To satisfy customers, the company provides the users with before-sale, in-sale and post-sale full respect services.

Item of service

·Technical training Equipment evaluation

·Installation and debugging Troubleshoot

·Maintenance Update and improvement

Commitment to the service

√ One-year warranty. Provide technical support free all-life of the products.

√ Keep all-life contacting with clients, get feedback on use of the equipment and make the products quality continually perfected.

√ Hot-line of service is available in 24h, responded in 8h.